GAP1605: Carlo Gavazzi DuplineReliable Industrial Control

1. Introduction

In the field of modern industrial automation, real-time communication, distributed control, and reliable data exchange are essential for ensuring process efficiency and stability. Carlo Gavazzi, a globally recognized leader in industrial electronics, has developed a wide range of devices designed to simplify automation systems through its innovative Dupline® fieldbus technology.

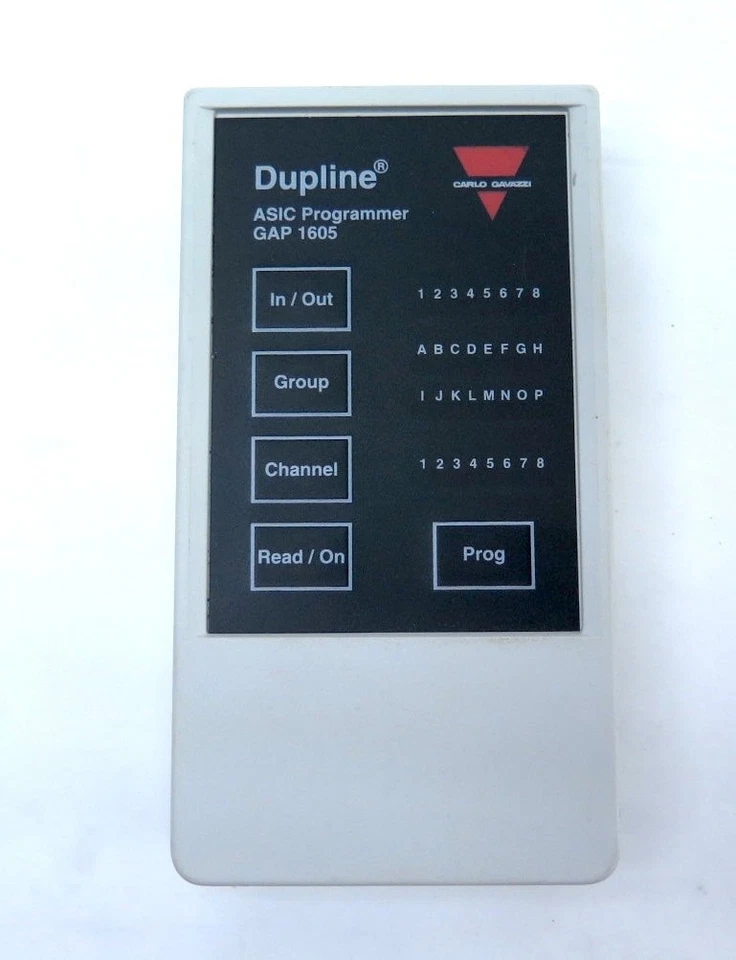

One of the key components of this system is the GAP1605 fieldbus operator panel, a versatile and intelligent human–machine interface (HMI) that allows users to monitor, configure, and manually control various Dupline devices in the field.

The Dupline system manual controller GAP1605 combines the simplicity of a two-wire fieldbus with the flexibility of local operation. It serves as a powerful communication interface between the operator and the Dupline network, allowing system engineers and technicians to visualize parameters, control outputs, and diagnose network status directly on-site — without additional programming software or complex wiring.

In this article, we will explore in depth the design, functionality, and technical specifications of the Carlo Gavazzi Dupline controller GAP1605, as well as its practical applications and advantages within different industrial and building automation environments.

2. Understanding the Dupline Fieldbus System

2.1 What Is the Dupline System?

The Dupline system is a universal, two-wire digital communication network developed by Carlo Gavazzi for distributed industrial and building automation. Unlike traditional point-to-point wiring, Dupline transmits signals, data, and commands via a single pair of wires, drastically simplifying installation and reducing cost.

Dupline can handle analog and digital signals, alarms, temperature readings, and even process control data across long distances, making it a highly versatile fieldbus platform. Its modular nature allows the integration of sensors, actuators, input/output modules, and operator panels like the GAP1605 under one unified communication protocol.

2.2 Benefits of the Dupline Fieldbus

- Two-wire simplicity: Combines power and data on the same pair of wires.

- Long-distance communication: Up to several kilometers without signal degradation.

- Noise immunity: Designed for harsh industrial environments with high EMI levels.

- Decentralized architecture: Simplifies wiring and reduces control cabinet complexity.

- Scalability: Easy to expand systems by adding new modules or devices.

In this environment, the GAP1605 fieldbus operator panel becomes the human interface that brings clarity and control to the system, acting as the bridge between user commands and the distributed Dupline network.

3. Overview of the GAP1605 Fieldbus Operator Panel

3.1 Functional Role

The GAP1605 is a compact operator panel specifically designed for direct integration into Dupline fieldbus networks. It allows operators to monitor system parameters, activate or deactivate outputs, and adjust control settings through a menu-driven interface.

The device is typically installed in local panels, machine control boxes, or building management systems, enabling engineers to access network information without needing to connect to a PC or central controller.

3.2 Typical Applications

- Industrial process control systems

- Building automation (lighting, HVAC, access control)

- Utility management and energy distribution

- Remote pump and valve stations

- Machine monitoring and fault diagnostics

4. Technical Specifications of GAP1605

The Carlo Gavazzi Dupline controller GAP1605 is designed to meet the demanding requirements of field operators and system engineers. Its specifications emphasize reliability, simplicity, and adaptability.

4.1 Electrical Characteristics

- Power Supply: 15–30 VDC or directly powered via the Dupline network

- Power Consumption: Typically < 1 W

- Communication Interface: Dupline 2-wire bus

- Galvanic Isolation: Between bus and local circuits

4.2 Display and Interface

- Display Type: Backlit LCD screen, 2 or 4 lines

- Display Resolution: 16–20 characters per line, alphanumeric

- User Interface: Four front-panel navigation buttons (Up, Down, Enter, Escape)

- Indicators: LED status lights for power, communication, and alarm

4.3 Mechanical Design

- Housing Material: Polycarbonate or ABS, flame-retardant

- Mounting: Panel-mount or wall-mount

- Protection Class: IP40–IP65 (depending on installation)

- Dimensions: Approx. 96 × 96 × 60 mm

- Weight: 250–300 g

4.4 Environmental Conditions

- Operating Temperature: –20 °C to +60 °C

- Storage Temperature: –30 °C to +80 °C

- Humidity: Up to 95% non-condensing

- Vibration Resistance: 10–55 Hz, 1.5 mm amplitude

These technical features make the Dupline system manual controller GAP1605 suitable for harsh industrial environments and outdoor installations, ensuring continuous operation under challenging conditions.

5. Performance and Functional Capabilities

5.1 Real-Time Monitoring and Control

The GAP1605 allows direct access to Dupline network variables such as digital inputs, outputs, and analog values. Operators can view sensor readings, control relays, or initiate commands in real time.

5.2 Menu-Driven Navigation

The intuitive LCD display provides menu-based operation, enabling quick access to configuration menus, data logs, and control functions without external programming tools.

5.3 Parameter Configuration

Users can configure I/O channels, setpoint values, thresholds, and timer parameters directly from the front panel. This capability eliminates the need for external controllers for minor adjustments or field modifications.

5.4 Diagnostics and Maintenance

The GAP1605 offers built-in diagnostic functions, including:

- Bus communication status

- Device addressing errors

- Input/output status

- Alarm and event logging

These features simplify maintenance and troubleshooting, significantly reducing downtime.

6. Integration with Dupline Controllers and Modules

6.1 System Architecture

In a typical Dupline installation, the GAP1605 connects to a Dupline master controller (such as the G3800 or G3490 series) through the two-wire bus. Input modules collect data from sensors, while output modules drive actuators. The GAP1605 acts as the local human interface for command and feedback.

[ Sensors / I/O Modules ] ←→ [ Dupline Bus ] ←→ [ GAP1605 ] ←→ [ Master Controller / PLC ]

6.2 Plug-and-Play Operation

Because the GAP1605 fieldbus operator panel communicates natively using the Dupline protocol, it automatically recognizes assigned channels and devices once connected to the network. This makes commissioning extremely fast and reliable.

6.3 Data Accessibility

All network data — such as temperature readings, digital states, or analog levels — can be displayed or modified directly on the GAP1605. This provides a decentralized approach to control and monitoring.

7. Advantages of the GAP1605 in Industrial and Building Automation

7.1 Simplified Wiring

With Dupline’s two-wire concept, installation complexity and cable cost are drastically reduced. The GAP1605 requires only two wires for both communication and power, minimizing field wiring effort.

7.2 Reliability and Robustness

Carlo Gavazzi’s Dupline technology is known for its resilience against electrical noise and its high level of communication integrity. Combined with the GAP1605’s rugged design, this ensures uninterrupted operation even in electromagnetically harsh environments.

7.3 Scalability

Adding new modules or operator panels is simple. The Carlo Gavazzi Dupline controller GAP1605 can easily be added to existing systems without reprogramming or hardware modification.

7.4 User-Friendly Interface

The backlit display and tactile keys provide clear visual feedback, enabling operators to perform quick status checks and manual operations directly in the field.

7.5 Maintenance Efficiency

Integrated diagnostic tools allow for rapid detection of network issues. Maintenance teams can isolate and resolve faults faster, ensuring high system uptime.

8. Typical Applications

8.1 Building Automation

The GAP1605 is widely used in intelligent building control systems for:

- Lighting and shading management

- HVAC control

- Access control and alarm monitoring

- Energy management and metering visualization

8.2 Industrial Process Control

In factories and production plants, the Dupline system manual controller GAP1605 enables:

- Monitoring of process parameters

- Manual override of outputs during commissioning

- Alarm indication for local operators

- Field adjustments of setpoints and calibration values

8.3 Infrastructure and Utility Systems

In water treatment, pumping stations, and energy distribution networks, the GAP1605 provides:

- On-site control capability without central supervision

- Local visualization of pump status or flow rate

- Seamless integration with Dupline I/O modules for distributed systems

9. Comparison with Conventional Operator Panels

Traditional operator panels or HMIs typically require complex programming, high-speed Ethernet or serial communication, and a dedicated power supply. In contrast, the Carlo Gavazzi Dupline controller GAP1605 offers:

- Direct Dupline connectivity (no gateway or converter needed)

- Power and data via the same two-wire line

- Simple addressing via Dupline channels

- Quick configuration through front-panel menus

This simplicity translates into lower engineering costs, faster setup, and easier maintenance — all critical advantages in large distributed automation systems.

10. Conclusion

The Carlo Gavazzi Dupline GAP1605 represents a highly efficient and user-oriented solution for distributed automation environments. By combining the proven robustness of the Dupline fieldbus system with an intuitive local operator interface, it enables engineers and technicians to manage, monitor, and control field devices with unprecedented simplicity.

With its compact design, reliable communication, and comprehensive diagnostic functions, the GAP1605 fieldbus operator panel is an indispensable tool in modern industrial and building automation systems.

Whether deployed in manufacturing facilities, energy management networks, or intelligent buildings, the Dupline system manual controller GAP1605 ensures flexibility, scalability, and long-term reliability — reflecting Carlo Gavazzi’s ongoing commitment to innovation and quality in automation technology.