NTCL01 Module Compatibility and Network Integration Methods Explained

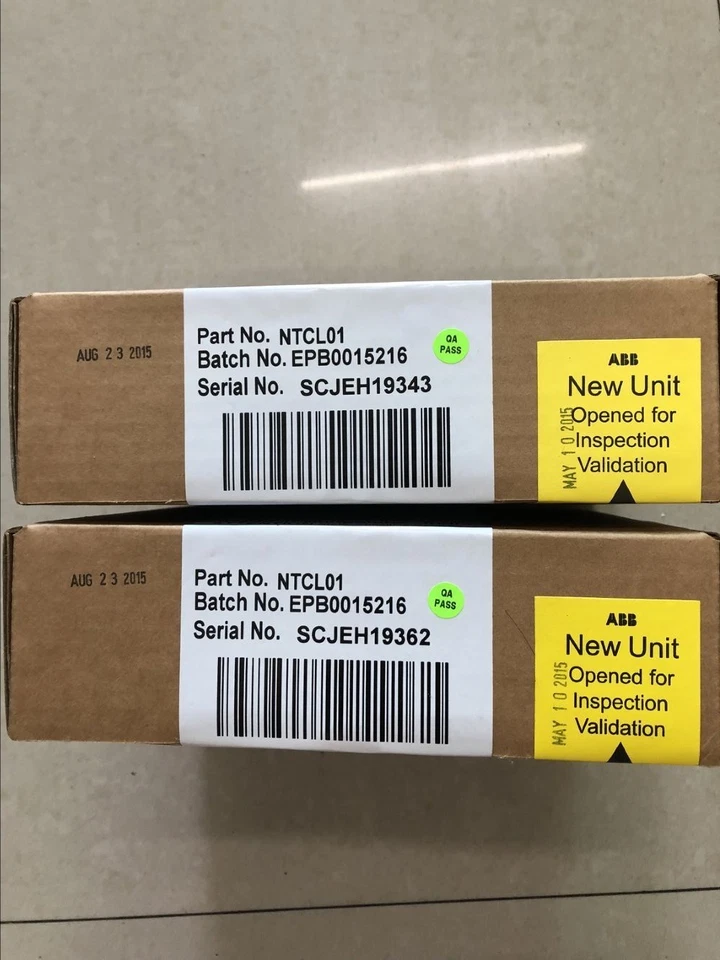

Introduction to ABB NTCL01 Module

The ABB NTCL01 module is a cornerstone in modern industrial automation, known for its robust functionality, reliability, and seamless integration capabilities. Understanding compatibility and network integration methods is crucial to fully leverage its potential. Correct implementation ensures efficient communication with controllers, PLCs, DCS systems, and other automation devices, enhancing overall system performance and reliability.

Importance of Compatibility in Industrial Automation

Ensuring Seamless System Integration

Compatibility is critical for maintaining stable communication and data integrity in automation networks. The NTCL01 module is engineered to interface smoothly with ABB systems, supporting various industrial protocols and reducing integration challenges.

Reducing Downtime and Operational Risks

Incompatible modules can lead to system errors, data loss, and unplanned downtime. Selecting and configuring the NTCL01 module properly prevents operational disruptions, safeguarding both production and safety.

Supporting Future Expansion

Compatibility ensures that the NTCL01 module can be integrated into evolving automation systems. Its ability to support future upgrades and expansions is essential for long-term operational planning.

Technical Compatibility Features of NTCL01

Communication Protocol Support

The ABB NTCL01 module supports a range of communication protocols including ABB proprietary protocols and standard industrial protocols such as Modbus and Profibus. This flexibility allows integration with both ABB and third-party systems.

Electrical and Signal Compatibility

The NTCL01 is designed to handle multiple input and output signal types, both analog and digital. Proper configuration ensures accurate signal processing, reducing errors and improving system responsiveness.

Environmental Compatibility

Built to withstand industrial conditions, the module operates reliably under temperature fluctuations, humidity, vibration, and electromagnetic interference. Its design ensures consistent performance across diverse environments.

Firmware and Software Updates

ABB provides firmware and software updates to maintain compatibility with evolving network protocols and automation systems. Regular updates enhance functionality and prevent obsolescence.

Methods for Network Integration

Step 1: Planning Network Architecture

Before integration, assess system requirements including the number of devices, signal types, and communication protocols. Ensure the NTCL01 module fits seamlessly within the existing architecture.

Step 2: Configuring Communication Settings

Set IP addresses, protocol parameters, and signal mappings according to system specifications. Correct configuration is essential for reliable data exchange between the NTCL01 module and controllers.

Step 3: Physical Connection Setup

Ensure proper cabling, secure connectors, and appropriate shielding to prevent signal degradation. Use standardized interfaces and follow ABB installation guidelines for best performance.

Step 4: Software Integration

Integrate the NTCL01 module into SCADA, HMI, or DCS systems using ABB’s configuration tools. Verify device recognition, signal accuracy, and correct mapping of I/O points.

Step 5: Testing and Validation

Conduct thorough testing to ensure stable communication, accurate signal processing, and fault-free operation. Validate network performance under typical and peak load conditions to guarantee reliability.

Troubleshooting Integration Issues

Common Issues

-

Signal mismatch between module and controller

-

Protocol incompatibility

-

Electrical interference causing communication errors

-

Improper firmware versions

Solutions

-

Verify protocol configuration and update firmware

-

Use shielded cables and proper grounding to reduce interference

-

Re-map signals in configuration software to match system requirements

-

Conduct environmental checks to ensure compliance with operating conditions

Best Practices for NTCL01 Network Integration

Use Standardized Protocols

Leveraging standard industrial protocols ensures compatibility with multiple devices and simplifies future network expansions.

Maintain Documentation

Keep detailed records of network configurations, firmware versions, and device mappings to facilitate maintenance and troubleshooting.

Implement Redundancy

Where critical operations are involved, implement network redundancy to prevent communication failures and ensure continuous operation.

Regular Monitoring

Utilize monitoring tools to track network performance, detect anomalies, and perform preventive maintenance on the NTCL01 module.

Advantages of Proper Network Integration

Enhanced System Reliability

Correct integration ensures stable communication and reduces system failures, supporting consistent industrial operations.

Optimized Performance

Accurate signal processing and timely data exchange improve process efficiency and control responsiveness.

Scalability and Flexibility

Proper network design allows seamless addition of new modules and devices, supporting system growth without major redesigns.

Reduced Maintenance Costs

Reliable integration minimizes troubleshooting time and maintenance interventions, lowering operational expenses.

Case Studies

Manufacturing Industry

A global manufacturing plant integrated NTCL01 modules into its existing PLC network. Result: Reduced communication errors by 40% and improved system uptime.

Power Generation

In a power plant, NTCL01 modules were integrated into a distributed control network. Result: Enhanced real-time monitoring, improved fault detection, and stable turbine control.

Chemical Processing Facility

NTCL01 modules were implemented with ABB DCS systems. Result: Improved process control accuracy, faster fault response, and minimized downtime.

Advanced Integration Techniques

Redundant Network Architecture

Implementing dual communication paths for critical modules ensures uninterrupted operation even if one network path fails.

Predictive Monitoring

Using advanced diagnostics in the NTCL01 module, operators can predict network issues before they impact production, supporting proactive maintenance.

Integration with IIoT Platforms

NTCL01 modules can be connected to Industrial Internet of Things (IIoT) platforms, enabling advanced analytics, remote monitoring, and smart automation capabilities.

Future-Proofing Network Integration

Firmware and Software Updates

Regularly updating module firmware ensures ongoing compatibility with new network protocols and automation technologies.

Modular Expansion

The NTCL01 module supports modular expansion, allowing seamless addition of devices and integration into evolving network architectures.

Supporting Industry 4.0 Initiatives

Proper network integration positions the NTCL01 module as a foundation for smart manufacturing, predictive maintenance, and real-time data-driven decision-making.

Summary

The ABB NTCL01 module excels in compatibility and network integration, making it a reliable choice for diverse industrial automation applications. Understanding its technical features, communication capabilities, and proper integration methods ensures stable operation, high performance, and system scalability.

By following best practices—including careful network planning, proper configuration, standardized protocols, and continuous monitoring—industrial operators can maximize the value of NTCL01 modules, reduce downtime, and support long-term automation strategies.

Properly integrated ABB NTCL01 modules not only enhance system reliability and operational efficiency but also provide a future-proof foundation for Industry 4.0, IIoT, and smart industrial automation initiatives.